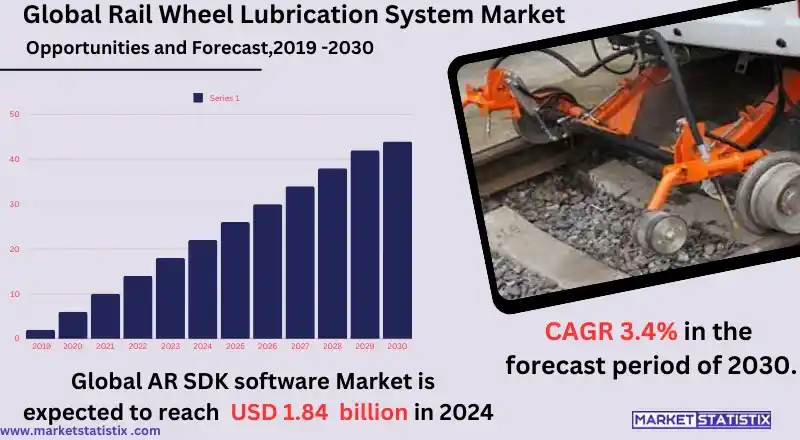

Global Rail Wheel Lubrication System Market Size, Share & Trends Analysis Report, Forecast Period, 2024-2030

Report ID: MS-87 | Automation and Process Control | Last updated: Oct, 2024 | Formats*:

Rail Wheel Lubrication System Report Highlights

| Report Metrics | Details |

|---|---|

| Forecast period | 2019-2030 |

| Base Year Of Estimation | 2023 |

| Growth Rate | CAGR of 3.4% |

| By Product Type | Solid Stick System, Spray System |

| Key Market Players |

|

| By Region |

Rail Wheel Lubrication System Market Trends

There are several distinct trends currently present in the Rail Wheel Lubrication System Market, and these are expected to shape the future growth of the market. One of the most prominent trends is the rising inclination towards the use of green lubricants. With rail operators and manufacturing companies going all out to be carbon neutral, there is a shift toward lubricants that are capable of degrading over time as well as those that are less harmful to the environment. Such trends are not only beneficial from the perspective of achieving global objectives on sustainability but also help improve the functionality of the rail systems by reducing the wear and tear of their parts, thus making them last longer and cutting down the maintenance costs. Integration of different advanced technologies like IoT and data analytics into lubrication systems is another key trend. With the help of these technologies, the systems facilitate condition-based monitoring and maintenance, meaning that the lubrication practices are more effective and faster. In this case, the use of data analytics allows the scheduling of lubrication systems to be based on the wear and tear of the parts and the surrounding environment that the machine works on.Rail Wheel Lubrication System Market Leading Players

The key players profiled in the report are SKF,, REBS Zentralschmiertechnik,, Baier & Koppel,, Secheron Hasler,, LB Foster, Schunk,, Bijur Delimon International,, Rowe Hankins,, Mersen,, Futec Origin.Growth Accelerators

The key factor fuelling the growth of the rail wheel lubrication system market is the growing need for advanced and eco-friendly solutions for railway transportation. With the increasing rise of freight and passenger rail services, effective lubrication systems aimed at minimising friction, enhancing safety, and combating wear and tear on railway parts are of utmost importance. The use of these systems not only enhances the performance of the train but also reduces the energy consumption as well as the expenses for maintenance, thus appealing to rail operators who are interested in improving their operations. Another important factor driving the growth of the market is the development of new and improved lubrication solutions. It includes the use of devices like automatic lube systems and also non-toxic lubricants that improve the usability of rail wheel lubrication systems. Environmental concerns created a new market for vegetable-based lubricants that perform well and are within the new workable boundary environmental regulations. Furthermore, the attention to safety in the rail industry has also brought about widespread usage of these systems in order to reduce the danger of failures and accidents.Rail Wheel Lubrication System Market Segmentation analysis

The Global Rail Wheel Lubrication System is segmented by Type, Application, and Region. By Type, the market is divided into Distributed Solid Stick System, Spray System . The Application segment categorizes the market based on its usage such as High Speed Trains, Freight Trains, Passenger Trains, Others. Geographically, the market is assessed across key Regions like {regionNms} and others, each presenting distinct growth opportunities and challenges influenced by the regions.Competitive Landscape

The rail wheels lubrication systems market is very competitive and has several long-standing companies as well as new entrants. The established companies in the market include SKF, Timken, NSK, Schaeffler, Wabtec, and many more. These companies have a variety of rail wheel lubrication systems in their inventory, such as grease lubrication systems, oil lubrication systems, and even water-based lubrication systems. The competition in this industry is fierce and involves distinct products, improvement of existing products, and development of new ones that will satisfy the growing demand in the rail industry. With increasing demand for rail transport, the market for rail wheel lubrication systems is likely to remain active and competitive as new entrants and new products are bound to come up against the incumbents.Challenges In Rail Wheel Lubrication System Market

The Rail Wheel Lubrication System Market experiences numerous challenges that can significantly limit its growth. One major issue is the low utilisation of public transport services and the high affinity for personal vehicles. With increasing disposable incomes, more customers prefer private automobiles, which reduces the need for rail transport, thereby eliminating the need for rail wheel lubrication systems. Also, in areas with **poorly developed railway systems** or where the infrastructure is generally low, this sophisticated lubrication system may not be embraced. Backward rail practices may lead to low-grade lubricants being used, hence undermining the life span of rolling stock and the efficiency of operations. Another problem is related to compliance with environmental policies and regulations. There is an absolute necessity for the industry to embrace more sustainable practices, including the use of eco-friendly lubricants and consumables, which may be very good from a health point of view but may come at a price in terms of performance in some cases compared to the organic solvents used to perform these activities. These factors all add up to a maze that the rail operators have to deal with when it comes to lubrication on board trains, apart from making sure that waste management is done satisfactorily while making returns.Risks & Prospects in Rail Wheel Lubrication System Market

The growth of the rail wheel lubrication system market can be attributed to the increasing requirements for effective and eco-friendly rail transport systems. In addition to expansion, the existing global rail networks are undergoing a modernisation phase, whereby there is demand for sophisticated lubrication systems that improve the operational performance and reduce maintenance costs for the railways. Growth in this sector is mainly attributed to technology improvements such as smart lubrication systems that improve performance by using environmentally friendly lubricants. In addition to that, the growing concern for minimisation of wear and tear for railway equipment presents a new market trend for the global players. Furthermore, automation of the lubrication processes not only enhances the efficiency of the processes but also reduces the likelihood of human error and delays due to equipment breakdown. More companies are focusing on research and development so as to develop varieties of products that can sell in markets that have tough environmental standards. The buoyant growth in passenger and freight railways, particularly in developing countries, is expected to create more opportunities for development within this market segment, thereby making it appealing to investment and development.Key Target Audience

The Rail Wheel Lubrication System Market is mainly targeted at two key groups: those in charge of locomotive operation as well as freight and passenger companies. Such organisations need proper lubrication systems in order to maintain the workings of their railways and prolong the life of their rail systems, in this case, bringing down the maintenance expenses as well as increasing efficiency of operations.,, Another important part of the target audience is made up of providers of regular maintenance and repair services and contractors for maintenance of the railway structures. These people maintain the effective and safe operation of railways and utilise lubrication systems; hence, they are the end-users of these systems. Overall, the market involves the interests of various parties, inclusive of those who seek to improve rail operations through enhanced lubrication.Merger and acquisition

The global market for rail wheel lubrication systems has undergone numerous mergers and acquisitions in the last few years, caused by the companies' attempts to take a variety of product lines, strengthen their market positions, and obtain new technologies, among others. Some of these are: Fuchs SE's purchase of Strub & Co. AG: In September 2024, Germany-based lubricant manufacturing company Fuchs SE revealed its plan of acquisition of Swiss lubricant firm Strub and Co. AG. It is assumed that this acquisition will put Fuchs in a better position in the rail lubricants market, especially in Europe. Shell's exit from the Singapore refining hub: In May 2024, Shell revealed that certain assets of the fuels and petrochemical complex located in Singapore would be reshuffled into a joint venture led by Chandra Asri, an Indonesian chemicals firm. Though this development doesn’t concern rail wheel hub lubrication systems directly, it illustrates very well the acute process of consolidation and layer restructuring that is occurring in the energy and chemicals sector in general. These acquisitions and mergers highlight the increasing significance of strategic alliances and consolidation in the rail wheel lubrication system market. Companies are now more focused on increasing the market share and the technology offering, which will push the M&A activity in this sector within a few years.- 1.1 Report description

- 1.2 Key market segments

- 1.3 Key benefits to the stakeholders

2: Executive Summary

- 2.1 Rail Wheel Lubrication System- Snapshot

- 2.2 Rail Wheel Lubrication System- Segment Snapshot

- 2.3 Rail Wheel Lubrication System- Competitive Landscape Snapshot

3: Market Overview

- 3.1 Market definition and scope

- 3.2 Key findings

- 3.2.1 Top impacting factors

- 3.2.2 Top investment pockets

- 3.3 Porter’s five forces analysis

- 3.3.1 Low bargaining power of suppliers

- 3.3.2 Low threat of new entrants

- 3.3.3 Low threat of substitutes

- 3.3.4 Low intensity of rivalry

- 3.3.5 Low bargaining power of buyers

- 3.4 Market dynamics

- 3.4.1 Drivers

- 3.4.2 Restraints

- 3.4.3 Opportunities

4: Rail Wheel Lubrication System Market by Type

- 4.1 Overview

- 4.1.1 Market size and forecast

- 4.2 Solid Stick System

- 4.2.1 Key market trends, factors driving growth, and opportunities

- 4.2.2 Market size and forecast, by region

- 4.2.3 Market share analysis by country

- 4.3 Spray System

- 4.3.1 Key market trends, factors driving growth, and opportunities

- 4.3.2 Market size and forecast, by region

- 4.3.3 Market share analysis by country

5: Rail Wheel Lubrication System Market by Application / by End Use

- 5.1 Overview

- 5.1.1 Market size and forecast

- 5.2 High Speed Trains

- 5.2.1 Key market trends, factors driving growth, and opportunities

- 5.2.2 Market size and forecast, by region

- 5.2.3 Market share analysis by country

- 5.3 Freight Trains

- 5.3.1 Key market trends, factors driving growth, and opportunities

- 5.3.2 Market size and forecast, by region

- 5.3.3 Market share analysis by country

- 5.4 Passenger Trains

- 5.4.1 Key market trends, factors driving growth, and opportunities

- 5.4.2 Market size and forecast, by region

- 5.4.3 Market share analysis by country

- 5.5 Others

- 5.5.1 Key market trends, factors driving growth, and opportunities

- 5.5.2 Market size and forecast, by region

- 5.5.3 Market share analysis by country

6: Rail Wheel Lubrication System Market by Wheel Type

- 6.1 Overview

- 6.1.1 Market size and forecast

- 6.2 Monoblock Wheels

- 6.2.1 Key market trends, factors driving growth, and opportunities

- 6.2.2 Market size and forecast, by region

- 6.2.3 Market share analysis by country

- 6.3 Resilient Wheels

- 6.3.1 Key market trends, factors driving growth, and opportunities

- 6.3.2 Market size and forecast, by region

- 6.3.3 Market share analysis by country

- 6.4 Rubber Tyred Wheels

- 6.4.1 Key market trends, factors driving growth, and opportunities

- 6.4.2 Market size and forecast, by region

- 6.4.3 Market share analysis by country

- 6.5 Steel Tyred Wheels

- 6.5.1 Key market trends, factors driving growth, and opportunities

- 6.5.2 Market size and forecast, by region

- 6.5.3 Market share analysis by country

- 6.6 Other Special Wheels

- 6.6.1 Key market trends, factors driving growth, and opportunities

- 6.6.2 Market size and forecast, by region

- 6.6.3 Market share analysis by country

7: Rail Wheel Lubrication System Market by Axle Type

- 7.1 Overview

- 7.1.1 Market size and forecast

- 7.2 Hollow Axles

- 7.2.1 Key market trends, factors driving growth, and opportunities

- 7.2.2 Market size and forecast, by region

- 7.2.3 Market share analysis by country

- 7.3 Solid Axles

- 7.3.1 Key market trends, factors driving growth, and opportunities

- 7.3.2 Market size and forecast, by region

- 7.3.3 Market share analysis by country

8: Competitive Landscape

- 8.1 Overview

- 8.2 Key Winning Strategies

- 8.3 Top 10 Players: Product Mapping

- 8.4 Competitive Analysis Dashboard

- 8.5 Market Competition Heatmap

- 8.6 Leading Player Positions, 2022

9: Company Profiles

- 9.1 SKF

- 9.1.1 Company Overview

- 9.1.2 Key Executives

- 9.1.3 Company snapshot

- 9.1.4 Active Business Divisions

- 9.1.5 Product portfolio

- 9.1.6 Business performance

- 9.1.7 Major Strategic Initiatives and Developments

- 9.2 REBS Zentralschmiertechnik

- 9.2.1 Company Overview

- 9.2.2 Key Executives

- 9.2.3 Company snapshot

- 9.2.4 Active Business Divisions

- 9.2.5 Product portfolio

- 9.2.6 Business performance

- 9.2.7 Major Strategic Initiatives and Developments

- 9.3 Baier & Koppel

- 9.3.1 Company Overview

- 9.3.2 Key Executives

- 9.3.3 Company snapshot

- 9.3.4 Active Business Divisions

- 9.3.5 Product portfolio

- 9.3.6 Business performance

- 9.3.7 Major Strategic Initiatives and Developments

- 9.4

- 9.4.1 Company Overview

- 9.4.2 Key Executives

- 9.4.3 Company snapshot

- 9.4.4 Active Business Divisions

- 9.4.5 Product portfolio

- 9.4.6 Business performance

- 9.4.7 Major Strategic Initiatives and Developments

- 9.5 Secheron Hasler

- 9.5.1 Company Overview

- 9.5.2 Key Executives

- 9.5.3 Company snapshot

- 9.5.4 Active Business Divisions

- 9.5.5 Product portfolio

- 9.5.6 Business performance

- 9.5.7 Major Strategic Initiatives and Developments

- 9.6 LB Foster

- 9.6.1 Company Overview

- 9.6.2 Key Executives

- 9.6.3 Company snapshot

- 9.6.4 Active Business Divisions

- 9.6.5 Product portfolio

- 9.6.6 Business performance

- 9.6.7 Major Strategic Initiatives and Developments

- 9.7 Schunk

- 9.7.1 Company Overview

- 9.7.2 Key Executives

- 9.7.3 Company snapshot

- 9.7.4 Active Business Divisions

- 9.7.5 Product portfolio

- 9.7.6 Business performance

- 9.7.7 Major Strategic Initiatives and Developments

- 9.8

- 9.8.1 Company Overview

- 9.8.2 Key Executives

- 9.8.3 Company snapshot

- 9.8.4 Active Business Divisions

- 9.8.5 Product portfolio

- 9.8.6 Business performance

- 9.8.7 Major Strategic Initiatives and Developments

- 9.9 Bijur Delimon International

- 9.9.1 Company Overview

- 9.9.2 Key Executives

- 9.9.3 Company snapshot

- 9.9.4 Active Business Divisions

- 9.9.5 Product portfolio

- 9.9.6 Business performance

- 9.9.7 Major Strategic Initiatives and Developments

- 9.10

- 9.10.1 Company Overview

- 9.10.2 Key Executives

- 9.10.3 Company snapshot

- 9.10.4 Active Business Divisions

- 9.10.5 Product portfolio

- 9.10.6 Business performance

- 9.10.7 Major Strategic Initiatives and Developments

- 9.11 Rowe Hankins

- 9.11.1 Company Overview

- 9.11.2 Key Executives

- 9.11.3 Company snapshot

- 9.11.4 Active Business Divisions

- 9.11.5 Product portfolio

- 9.11.6 Business performance

- 9.11.7 Major Strategic Initiatives and Developments

- 9.12 Mersen

- 9.12.1 Company Overview

- 9.12.2 Key Executives

- 9.12.3 Company snapshot

- 9.12.4 Active Business Divisions

- 9.12.5 Product portfolio

- 9.12.6 Business performance

- 9.12.7 Major Strategic Initiatives and Developments

- 9.13

- 9.13.1 Company Overview

- 9.13.2 Key Executives

- 9.13.3 Company snapshot

- 9.13.4 Active Business Divisions

- 9.13.5 Product portfolio

- 9.13.6 Business performance

- 9.13.7 Major Strategic Initiatives and Developments

- 9.14 Futec Origin.

- 9.14.1 Company Overview

- 9.14.2 Key Executives

- 9.14.3 Company snapshot

- 9.14.4 Active Business Divisions

- 9.14.5 Product portfolio

- 9.14.6 Business performance

- 9.14.7 Major Strategic Initiatives and Developments

10: Analyst Perspective and Conclusion

- 10.1 Concluding Recommendations and Analysis

- 10.2 Strategies for Market Potential

Scope of Report

| Aspects | Details |

|---|---|

By Type |

|

By Application |

|

By Wheel Type |

|

By Axle Type |

|

Report Licenses

Our Team

Frequently Asked Questions (FAQ):

How do regulatory policies impact the Rail Wheel Lubrication System Market?

+

-

What major players in Rail Wheel Lubrication System Market?

+

-

What applications are categorized in the Rail Wheel Lubrication System market study?

+

-

Which product types are examined in the Rail Wheel Lubrication System Market Study?

+

-

Which regions are expected to show the fastest growth in the Rail Wheel Lubrication System market?

+

-

What are the major growth drivers in the Rail Wheel Lubrication System market?

+

-

Is the study period of the Rail Wheel Lubrication System flexible or fixed?

+

-

How do economic factors influence the Rail Wheel Lubrication System market?

+

-

How does the supply chain affect the Rail Wheel Lubrication System Market?

+

-

Which players are included in the research coverage of the Rail Wheel Lubrication System Market Study?

+

-